Are you struggling with stubborn nuts and bolts during your repair or construction works? An Impact wrench, a powerful tool primarily used to tighten or loosen bolts, can be your game-changer. But, how to use an impact wrench exactly?

When using an impact wrench, first make sure it’s powered up. Next, choose the correct socket for your bolt. Secure the item you’re working on and fit the socket snugly onto it. Use the wrench’s trigger to turn the bolt or nut, ensuring not to over-tighten.

This comprehensive guide is designed to take you through the basic steps of using an impact wrench effectively and safely, saving you time and reducing fatigue.

Let’s dive right in to explore this handy power tool that can make your work easier!

Table of Contents

The Basics of Using an Impact Wrench

First, take a look at the part you will use the impact wrench on. It might be a car tire lug nut or a big bolt. Take note of its size and shape. You need to do this before you choose your tools.

Know what piece you need to fasten or loosen with your wrench. Make sure it’s strong enough for the force from an impact wrench. Doing so helps make sure nothing bad happens when you use your tool later on.

Set up your impact wrench

To set up your impact wrench, start by choosing the right-sized socket for the job. Make sure it matches the size of the fastener you’ll be working with. Once you have the socket, attach it securely to the wrench.

Hold the impact wrench firmly with both hands and position it at a right angle to the fastener. This will allow for better control and prevent any accidental slips or damage. With everything in place, you’re ready to start using your impact wrench effectively!

Use a torque stick (for fastening)

To ensure proper fastening, it is recommended to use a torque stick with your impact wrench. A torque stick is a special tool that helps prevent overtightening of bolts and nuts. It works by flexing under pressure, which limits the amount of torque being applied.

This helps prevent damage to the workpiece or stripped threads. By using a torque stick, you can achieve accurate and consistent tightening without the need for manual adjustment or guesswork.

Make sure to select the correct torque stick based on the desired level of tightness specified for your specific application.

Attach a socket

To attach a socket to your impact wrench, choose the appropriate size socket for the job. Make sure it matches the size of the fastener you are working with. Then, securely place the socket onto the square drive of the impact wrench and lock it in place.

It’s important that the socket is properly attached to ensure a safe and effective operation.

Start the fastener by hand (for fastening)

To start fastening with an impact wrench, it’s important to begin by hand. This means using your own strength to turn the fastener a few rotations before letting the impact wrench take over.

Starting by hand ensures that the fastener is properly aligned and prevents cross-threading or damage to the threads. It also helps prevent overtightening, which can strip or stretch the threads.

So always remember to give it a few turns by hand before letting the power of the impact wrench do its job!

Apply gradual power

To use an impact wrench effectively, it’s important to apply power gradually. This means starting with a lower power setting and increasing it as needed. By doing this, you can avoid overtightening or stripping the threads of the fastener.

Applying gradual power also helps ensure that the torque is delivered evenly, preventing any damage to the workpiece or the tool itself. So remember, start with less power and gradually increase it until the fastener is securely tightened without causing any harm.

Safety Precautions when Using an Impact Wrench

To use an impact wrench properly, it’s important to use the right-sized bit or socket. Mismatched sizes can cause damage to both the fastener and the tool itself. Make sure you choose a socket that fits snugly onto the nut or bolt you’re working on.

Using the correct size will ensure a secure grip and prevent slipping or stripping of threads. So always double-check and select the appropriate socket before using your impact wrench for a smooth and efficient operation.

Avoid cross-threading

When using an impact wrench, it’s important to avoid cross-threading. Cross-threading occurs when the fastener and the threaded hole do not align properly, causing the threads to become damaged or stripped.

This can make it difficult to tighten or loosen the fastener correctly and may result in a weaker connection. To prevent cross-threading, always start by hand-tightening the fastener before using the impact wrench.

Take your time to ensure that the threads are aligned properly before applying power with the tool. By being cautious and attentive, you can avoid damaging both your workpiece and your impact wrench itself while achieving secure and effective fastenings.

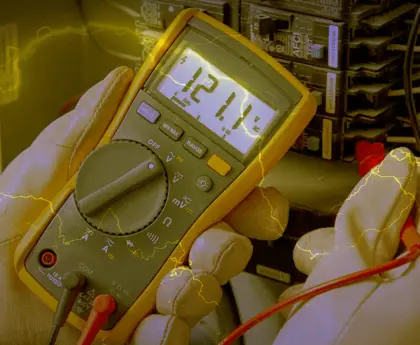

Familiarize yourself with the power source

Before using an impact wrench, it is important to familiarize yourself with the power source. This means understanding how the tool gets its power and ensuring it is properly connected or charged.

Impact wrenches can be powered by either air or battery. If using an air-powered impact wrench, you will need an air compressor to provide the necessary compressed air. Make sure the compressor is set up correctly and that you have a sufficient supply of air.

For battery-powered impact wrenches, ensure that the battery is fully charged before starting your work. It’s also important to know how long the battery will last so you can plan accordingly.

Avoid overtightening

Overtightening is something you should try to avoid when using an impact wrench. If you tighten a bolt or nut too much, it can cause damage to the fastener or the tool itself. This can lead to stripped threads, stretched bolts, or even breakage.

It’s important to apply just enough torque to secure the fastener without going overboard. Be mindful of how much force you’re applying and stop tightening once the fastener feels snug and secure.

By avoiding overtightening, you can prevent unnecessary damage and ensure that your impact wrench lasts longer.

Wear safety eyewear

Protecting your eyes is crucial when using an impact wrench. Wear safety eyewear to shield your eyes from any flying debris or particles that may be released during the tightening or loosening process.

This will help prevent eye injuries and ensure your safety while operating the tool.

Avoid using at an angle

Using an impact wrench at an angle can cause accidents and damage. It’s important to always use the tool at a right angle to the fastener. This ensures proper engagement and prevents the wrench from slipping off or causing injuries.

When using an impact wrench, make sure to hold it firmly with both hands and position it correctly for optimal performance. By avoiding angles, you’ll be able to safely and effectively tighten or loosen bolts without any problems.

Understanding Torque Settings on an Impact Wrench

The torque setting on an impact wrench is important for getting the right amount of tightening force. It determines how much power the tool will deliver to the fastener. To understand torque settings, you need to know that it is measured in foot-pounds (ft-lbs) or Newton-meters (Nm).

Different jobs require different levels of torque, and using too much or too little can cause problems. For example, if you apply too much torque, you may overtighten the fastener, which can lead to damage or stripped threads.

On the other hand, not applying enough torque can result in a loose connection that may come undone over time. So it’s crucial to choose the right torque setting based on what you’re working on and always refer to manufacturer guidelines or recommended specifications whenever possible.

Conclusion: How to use an impact wrench

In conclusion, learning how to use an impact wrench can make your projects easier and faster. By following the basic steps of setting up the tool, using the right socket, and applying gradual power, you can effectively tighten or loosen bolts with ease.

Just remember to always prioritize safety and avoid over-tightening to prevent any damage.