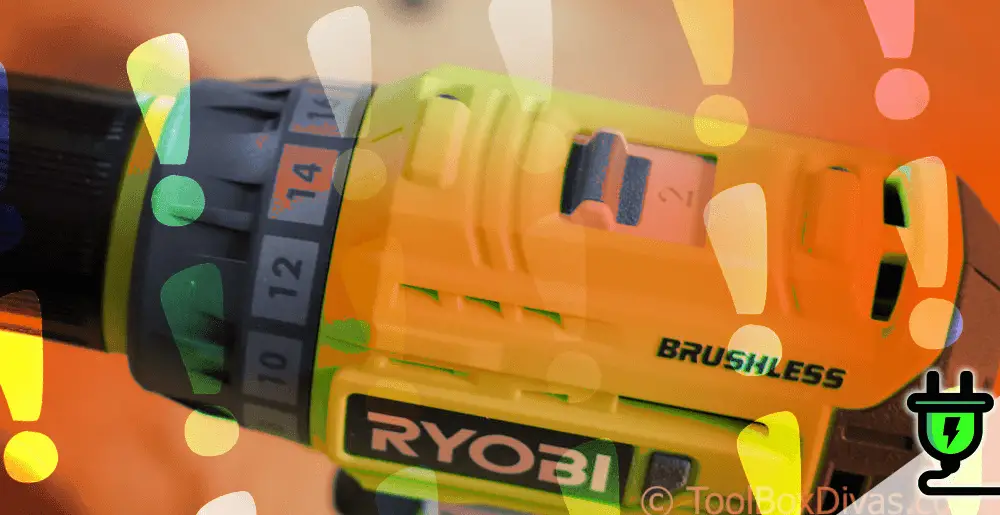

Looking at your new drill, you might be puzzled about what do the numbers mean on a drill? printed on it. Many people aren’t aware that these mysterious numbers control two crucial features of a drill: torque and speed.

The numbers on your drill correspond to different torque settings. A higher number indicates greater torque, suitable for driving larger fasteners. To modify the torque, turn the collar until the arrow points to a desired setting and begin screwing.

This guide is designed to demystify these figures – helping you understand their function, how they change the performance of your drill, and ultimately assisting in bettering your DIY projects.

Ready to decode those numerical mysteries? Let’s unravel the mystery of what do the numbers mean on a drill!

Understanding the Numbers on a Drill

The numbers on a drill represent the torque and speed settings, which determine the power and rotation speed of the drill.

Torque setting

The torque setting on a drill controls how much force the tool applies to a screw or other fastener. It’s represented by numbers typically found on the clutch of the drill. A higher number means more rotary force can be applied, maximizing the torquing capability of your tool.

For certain tasks that need intense power like driving long screws into tough material, you’ll want to use high torque settings. In contrast, for delicate operations where over-tightening could cause damage, a lower setting is preferred.

Understanding these settings enables you to make efficient use of your drill and perform tasks with precision and accuracy.

Speed setting

The speed setting on a drill refers to the revolutions per minute (RPM) at which the chuck will spin. This determines how fast the drill bit will rotate during drilling. Different speed settings are used for different tasks.

For example, a lower speed setting is typically used for low-speed applications that require high torque, such as driving screws into tough materials. On the other hand, a higher speed setting is used for high-speed applications like drilling holes in softer materials.

It’s important to choose the right speed setting based on the material being drilled and the desired outcome of your project.

Torque Settings and Their Uses

Different torque settings cater to specific applications, such as drilling into different materials or driving screws of varying sizes.

Different torque settings for different applications

The torque setting on a drill is an important feature that allows you to adjust the amount of force applied when driving screws or fasteners. It determines how much rotary force the tool will deliver.

Higher numbers on the drill indicate greater torque, while lower numbers are used for low-speed applications requiring high torque. Different applications require different levels of torque, so it’s crucial to choose the right setting for each task.

By selecting the appropriate torque setting, you can ensure efficient and accurate drilling while avoiding damage or over-tightening of fasteners.

Importance of using the correct torque setting

Using the correct torque setting is crucial when operating a drill. The torque setting determines the amount of force applied to the fastener, such as a screw, ensuring it is tightened to the proper level.

If too much torque is applied, there is a risk of over tightening or even damaging the fastener or material being drilled into. On the other hand, insufficient torque can result in loose screws that may come undone.

Therefore, selecting the appropriate torque setting based on the task at hand and following manufacturer guidelines is essential for achieving optimal results and preventing unnecessary damage or accidents.

Speed Settings and Their Uses

Different speed settings on a drill are designed for different tasks, allowing users to control the drilling efficiency and accuracy.

Different speed settings for different tasks

The speed settings on a drill are designed to accommodate various tasks and applications. Depending on the project at hand, you can adjust the speed of the chuck to suit your needs.

A lower speed setting is ideal for low-speed applications that require high torque, such as driving screws into tough materials or drilling through dense surfaces. On the other hand, a higher speed setting is perfect for high-speed applications like drilling into softer materials or creating holes quickly.

By selecting the appropriate speed setting, you can ensure optimal efficiency and accuracy in your drilling tasks.

Impact on drilling efficiency and accuracy

The numbers on a drill have a significant impact on drilling efficiency and accuracy. The torque setting determines the amount of force applied to the fastener, while the speed setting determines how fast the chuck spins.

By selecting the appropriate torque and speed settings, you can optimize your drilling performance. Higher torque settings are ideal for applications requiring more power and strength, ensuring that screws are securely tightened or removed.

On the other hand, lower speed settings provide greater control and precision when working with delicate materials or when using smaller drill bits. It’s crucial to choose the right settings based on your specific needs to achieve efficient and accurate drilling results every time.

Factors to Consider When Choosing the Right Setting

Factors to consider when choosing the right setting include the material being drilled, the size and type of drill bit, and the desired outcome.

Material being drilled

The material being drilled plays a crucial role in determining the appropriate torque and speed settings for your drill. Different materials require different levels of force to achieve efficient drilling.

For example, drilling into soft wood may require less torque compared to drilling into concrete or metal. By considering the type of material you’re working with, you can select the optimal torque setting on your drill to ensure smooth and effective drilling without causing any damage or excessive wear on the material.

Furthermore, the hardness and composition of the material can also impact the speed setting you should use. Harder materials like metal typically require slower speeds for better control and precision, while softer materials may allow for higher speeds.

Size and type of drill bit

The size and type of drill bit are important factors to consider when using a drill. The size refers to the diameter of the bit, which determines the size of the hole that will be drilled.

Different projects may require different sizes of drill bits in order to achieve the desired outcome. Additionally, the type of drill bit is also essential as there are various types available for different materials and applications.

For example, wood drilling bits are designed specifically for drilling through wood, while masonry bits are used for drilling into concrete or brick surfaces. It’s crucial to select the right size and type of drill bit based on your specific project needs in order to ensure accurate and efficient drilling results without damaging your materials or compromising safety.

Desired outcome

The desired outcome when using a drill is to achieve the right amount of torque and speed for the task at hand. By selecting the appropriate torque setting, you can ensure that the fastener is securely tightened without being over-torqued.

Similarly, choosing the correct speed setting allows you to control how rapidly the chuck spins, which impacts drilling efficiency and accuracy. Consider factors such as the material being drilled and the size/type of drill bit to determine the desired outcome and adjust your settings accordingly.

What do the numbers mean on a drill FAQs

How do I know which number to use on my drill?

The number you should use on your drill depends on the material you’re drilling into. Lower numbers are for softer materials, while higher numbers are for harder materials.

What happens if I use the wrong number setting on my drill?

Using the wrong number setting on your drill can cause the bit to spin too slowly or too quickly, leading to ineffective drilling or damaging the material.

Can I always rely on the recommended speed settings for my specific task?

While it’s generally safe to follow the recommended speed settings for your specific task, it’s still important to consider factors such as bit type and size, as well as personal experience and judgment when adjusting your drill’s speed.

Conclusion: What do the numbers mean on a drill?

Understanding the numbers on a drill is essential for using the tool effectively. The numbers represent torque settings and indicate the amount of force that can be applied. By knowing how to interpret these numbers, you can select the right setting for your specific drilling or fastening needs, ensuring optimal performance and results.